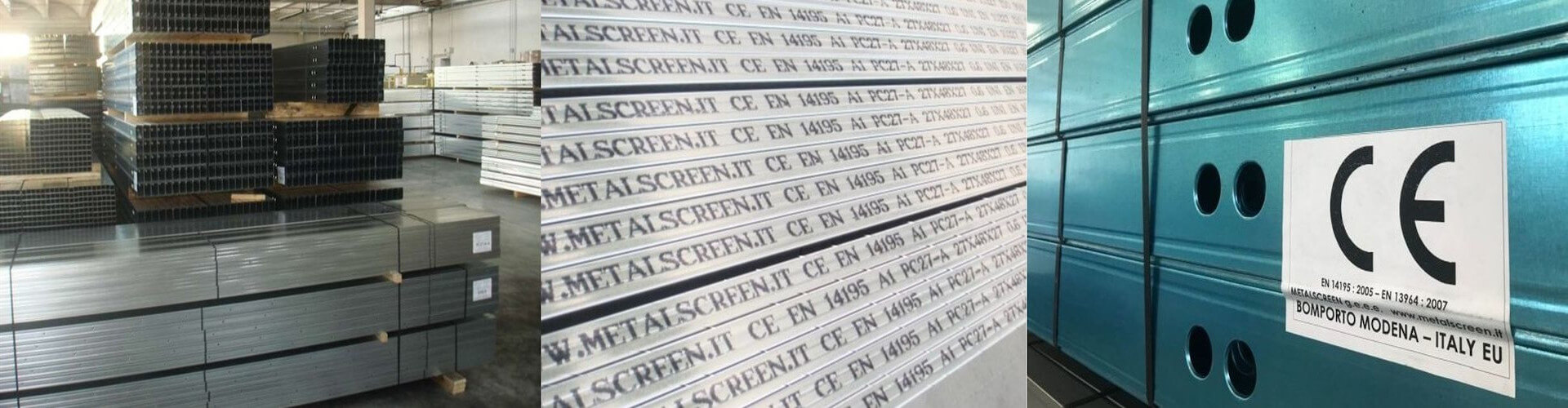

Italian excellence for architectural solutions

Cataloghi prodotti

Documentazione relativa a ogni tipologia di prodotto con specifiche di capitolato, schede tecniche, fotografie e disegni.

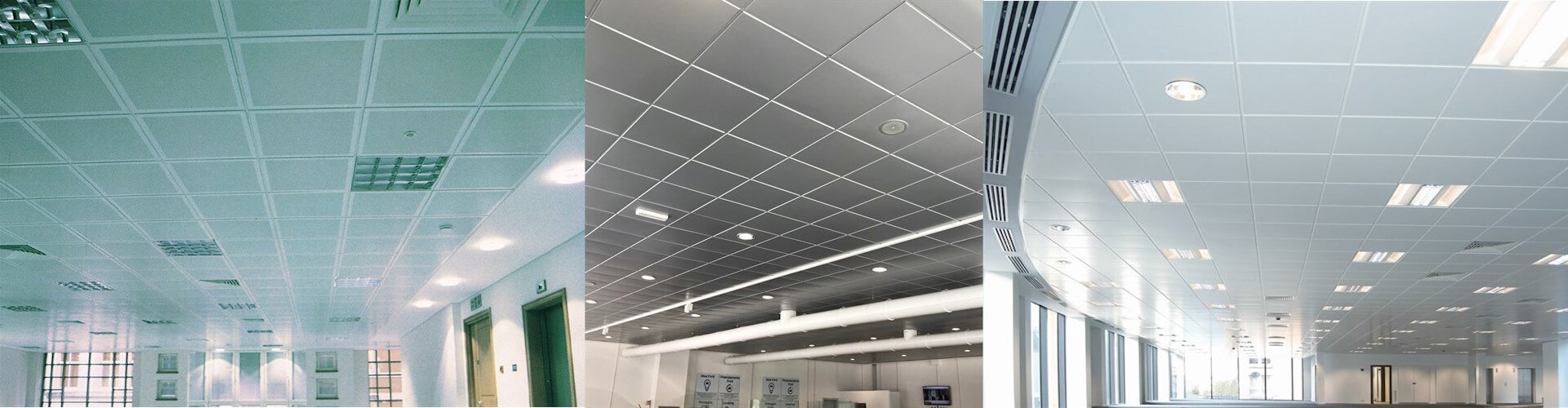

Controsoffitti metallici

Produzione di controsoffitti metallici in

acciaio zincato e alluminio preverniciato per appropriato impiego interno ed

esterno. Possono essere scelti pieni o microforati rivestiti con TNT acustico.

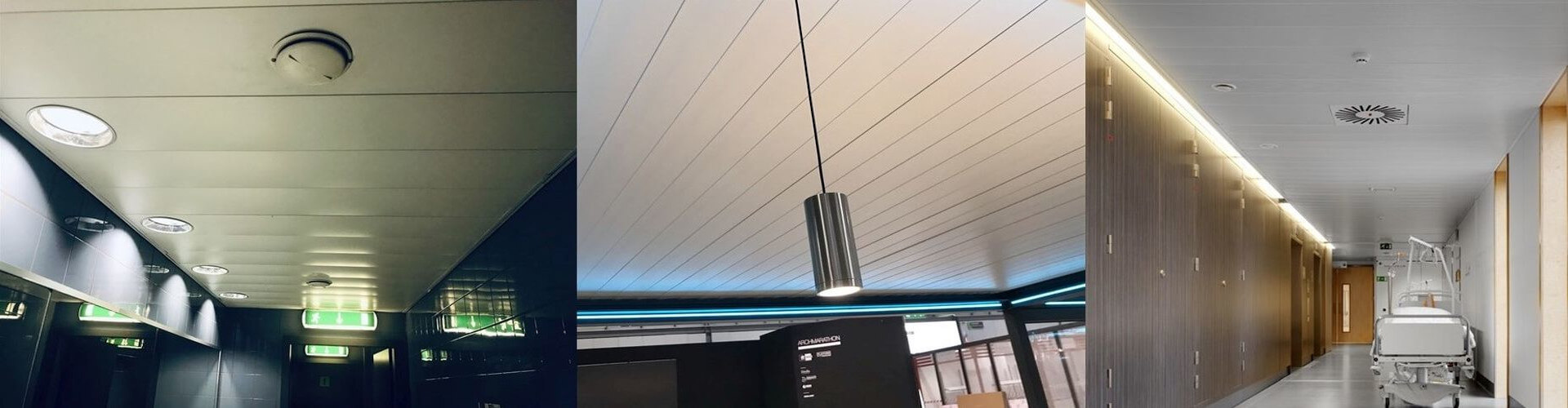

- Doghe modulari

mm.30-80-84-90-100-130-134-140-150-180-190-200-290-300;

- Grigliati Carabottino schermanti con base

mm.10-15 xh 40-50;

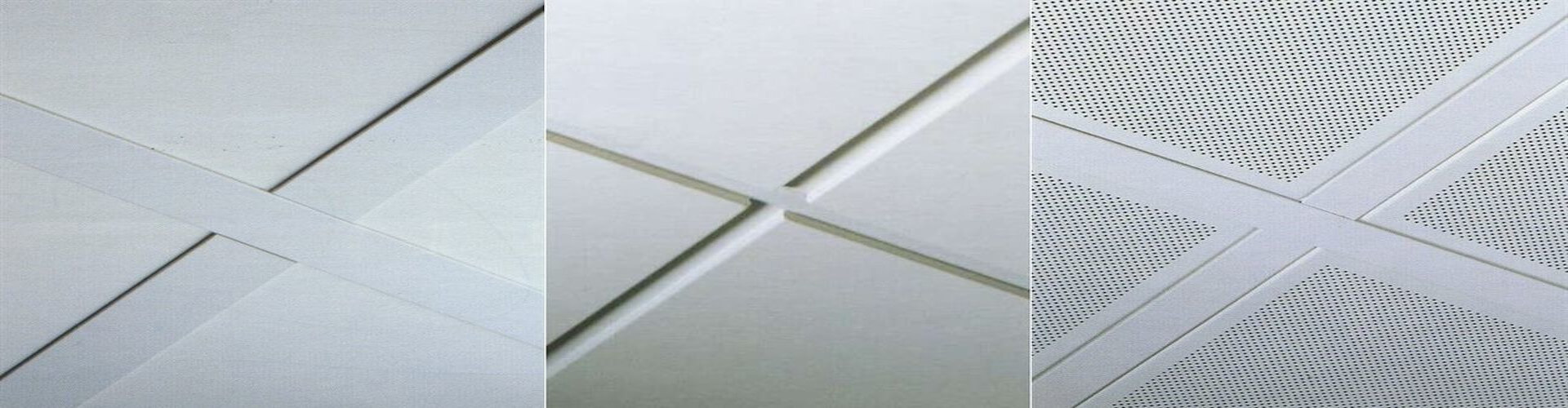

- Plafoni mm.600x600 in appoggio e struttura

nascosta.

Rivestimenti PER ESTERNO E INTERNO

Produzione di rivestimenti facciate esterne orizzontali e verticali realizzate con doghe modulari in alluminio preverniciato Coil Coating Incombustibile Euroclass A1.

Frangisole in alluminio

Frangisole schermante orizzontale e verticale ideale per l’utilizzo esterno. Le doghe a scatto mm.84R hanno un’inclinazione fissa di 30°- 45°- 65°/22° e sono realizzate in alluminio preverniciato Coil Coating Incombustibile Euroclass A1.

COLORI E FINITURE

I nostri prodotti sono disponibili in

diversi colori e finiture per permettervi la completa personalizzazione dei

vostri progetti:

CARTELLA RAL colori standard o realizzati

su richiesta da cartella RAL

WOOD LIKE effetto legno

OXIDAL effetto anodizzato spazzolato

ULTRA MATT effetto super opaco metallizzato